Download or print a PDF of this GIS

Overview

The prescribed gas installation standard, AS/NZS 5601.1 Gas installations Part 1: General installations, Appendix D – Purging, provides information about purging natural gas (NG) installations up to 0.03 m3 (30 litres).

This information sheet explains how to purge NG installations with volumes above 0.03 m3.

Note: For additional guidance on purging LP gas installations – See Gas Information Sheet 14B

What is purging?

Purging is the elimination of an undesirable substance from a gas pipe, piping system or appliance.

Why purge

Purging avoids the possibility of an explosive air and gas mixture forming in consumer piping, appliances, or confined spaces, and is defined as either the displacement of:

- air or an inert gas by a fuel gas (purging into service)

- a fuel gas by air or an inert gas (purging out of service).

Nitrogen is the preferred inert gas for purging a gas installation out of service.

When to purge

Purging out of service is performed after the gas supply has been isolated and prior to any gas work being performed.

Purging into service, to displace air or an inert gas with a fuel gas, must take place after the completion of gas work and immediately after a successful gas tightness test.

Properties of Natural Gas

Natural gas (NG):

- is lighter than air

- has a lower explosive limit (LEL) of 5% in air

- has an upper explosive limit (UEL) of 14% gas in air.

What to do before a purge

Before purging an installation, always ensure that:

- a plan of the pipe work system is available and has been checked for accuracy

- the purging procedure has been carefully planned (including the number of persons required to safely carry out the purge)

- no other work on the installation is taking place during the purging operation

- purge points are located at the end of the main run and the end of each branch

- a gas detector is on hand that is capable of measuring:

o % by volume of NG (0% to 100%)

o %LEL of NG (from 0% to 100%).

General points to remember when purging include:

- Energy Safe may request a written procedure for installation volumes larger than 0.03 m3 (30 litres)

- always keep vented gas amounts to a minimum for environmental reasons

- ensure that the pipe work is gastight and all open ends are sealed before allowing gas to enter

- the pressure created during purging should not exceed the design operating pressure and must not exceed the pipe’s tested pressure

- pipe work being permanently taken out of service must be physically isolated by removing a section of pipe work or by spading (inserting a physical barrier between sections of pipe)

- decommissioned pipe work must be left purged with inert gas

- the purging of the billing meter is performed by the gas distribution company.

Site preparation

Do not start purging until:

- the purge area has been defined, made safe, and cleared of all ignition sources (like naked flames, pilot lights, electrical switchgear, etc.)

- people concerned have been told that gas purging will take place

- a sufficient number of suitable fire extinguishers are situated near the venting point (personnel should be familiar with their use).

All electronic communication equipment to be used within the immediate vicinity of the purge discharge area must be intrinsically safe for use in hazardous areas, and there must be no smoking near the purge area. The purge discharge area must be controlled to ensure no ignition sources are introduced once purging begins.

Design and location of purging equipment

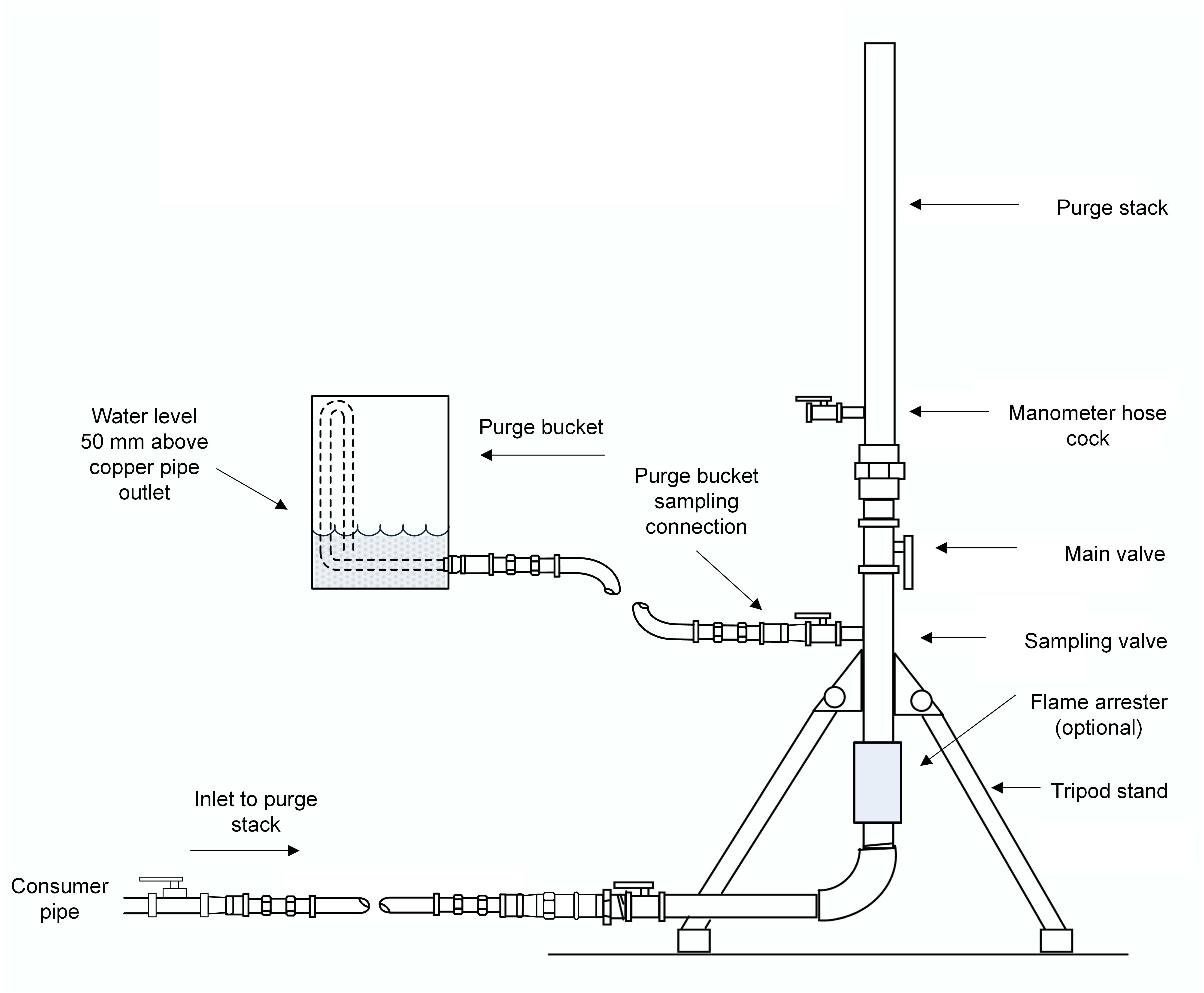

- Purged gas should be vented to the outside atmosphere and away from any buildings, air intakes or electrical ignition sources. A purge stack or a purge bucket may be required. Refer to Figure 2 for an example of a typical purging kit.

- Select a location where purged gases will be dispersed quickly and will not give rise to complaints about a smell of gas.

- Purging hoses must be suitable for containing the gas, be gastight and properly secured. Hose materials, such as polyethylene, could generate static electricity and must not be used.

- Energy Safe Victoria does not recommend the flaring of flammable gases during purging. If flaring is to be undertaken, special precautions, such as the fitting of a flame arrester on the flare stack, will be required.

Purging

Replacing air with natural gas (purging into service)

This procedure is:

- suitable for consumer piping with pipe sizes and lengths no greater than those stated in AS/NZS 5601.1:2022 - Table D.6 provided that no vessels, such as surge tanks for gas engines, are involved.

- applies to any consumer piping being commissioned for NG that has previously been purged with an inert gas.

Note: An inert gas purge is required for pipe lengths exceeding those listed in AS/NZS 5601.1:2022, Appendix D - Table D.6.

Purging a gas installation into service

- Calculate the volume of the main run of pipe before commencing the purge (refer to AS/NZS 5601.1:2022, Appendix D - Table D.4.1). Observing the volume passing through the meter will indicate when gas is expected to flow through the purge stack or the purge bucket.

- Note the meter test dial position.

- Connect the purge stack or the purge bucket to the furthest point on the main run.

- Open the control valves and commence the purge.

- Ensure the maximum purging pressure is not exceeded.

- Continue to purge through the purge stack or purge bucket until natural gas starts to emerge.

- Take a sample from the purge stack or purge bucket sampling point using a suitable gas detector (minimum acceptable reading 95% gas). An indication that the purging of natural gas is nearing completion is seen when a mass of bubbles lift off and float away from the purge bucket.

- Continue purging and testing until an acceptable reading is obtained.

- When the correct test result is obtained, the purge of this section of the installation will be complete.

- Relieve the pressure in the purge hose by opening the purge stack main valve.

- Disconnect the purge hose and the hose inlet valve from the installation, capping off immediately to avoid gas escaping and air re-entering the line.

- Transfer the purge stack or purge bucket and hose to the end of the branch nearest the gas meter and repeat the procedure.

- Continue purging all branches, moving away from the meter, until the installation is filled with NG.

Purging a gas meter

On large commercial industrial installations, the meter is normally purged by the gas company. For small meters or sub-meters allow five times the volume of gas held in the meter by observing the test dial. This will ensure that no trace of air or inert gas remains inside the gas meter body. The cyclic capacity of a meter is shown on its badge plate.

Purging through an appliance and an appliance fitted with a flame safeguard system

For information about purging through an appliance and an appliance fitted with a flame safeguard system, see - AS/NZS 5601.1:2022, Appendix D.4.4.

Testing for completion of a purge

There are several methods to confirm a complete purge; by taking a sample from the purge stack or purge bucket sampling point using a suitable gas detector (minimum acceptable reading 95% gas). An indication that the purging of natural gas is nearing completion is seen when a mass of bubbles lift off and float away from the purge bucket.

Once satisfied that the gas installation has been completely purged and now contains natural gas; you must ensure all sections of the gas line disconnected for purging are re-connected and leak tested for gas tightness.

Replacing air or natural gas with an inert gas (purging out of service)

The procedure for calculating the volume of inert gas is suitable for totally displacing all air or natural gas from a gas installation, and must be carried out where consumer piping (regardless of length or diameter) is being:

- decommissioned and a hazard may be created (for example when welding or cutting into the gas line may occur in the future)

- commissioned or decommissioned and contains a vessel (for example a surge tank that may contain a stored volume of gas).

When part of the consumer piping is being decommissioned, isolate this section from the consumer piping not being purged by an effective means (valve, spade or physical disconnection).

Special care should be taken where pressure vessels are involved. Consider using an appropriate specialist company to assist with planning the purge and analysing the gas samples.

Calculating the volume of inert gas required

All branches on a pipe section, regardless of length or diameter, must be purged. This example procedure uses nitrogen as the inert gas.

To determine the volume of nitrogen required to complete a purge:

- Determine the volume of the consumer piping including all the branches. See AS/NZS 5601.1:2022 Appendix D - Table D.4.1 for approximate volumes of pipe.

- Add all the volumes calculated in Step 1 and multiply by a factor of 1.5. This gives the total volume of nitrogen required to carry out the purge.

- Consult your nitrogen supplier and establish the number of nitrogen cylinders required to complete the purge. (An extra cylinder may be ordered as a precaution).

Nitrogen set pressures

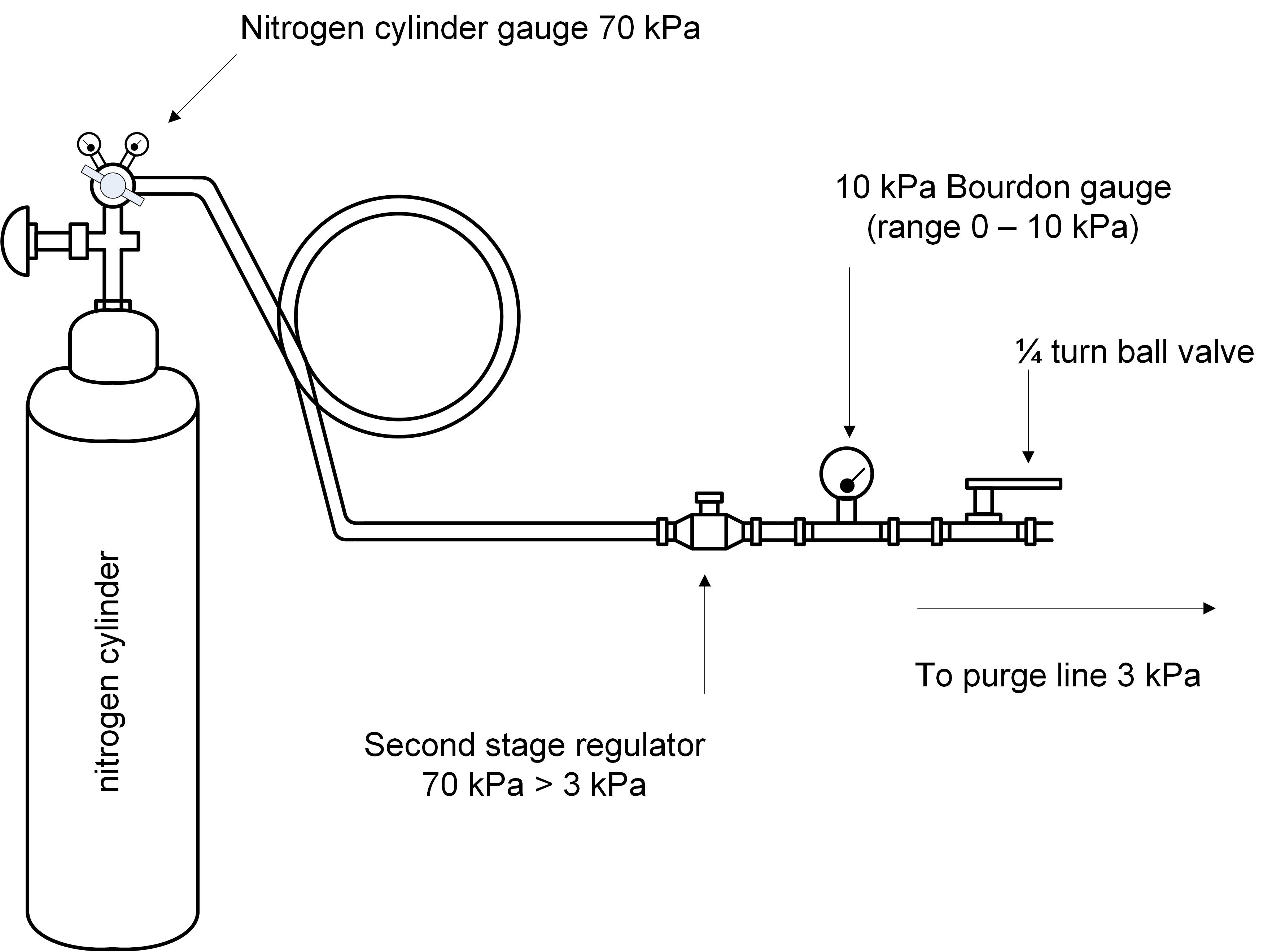

The setting pressure of the cylinder regulator is 70 kPa.

The second stage regulator is to be set to provide a flowing pressure of 3 kPa with a lock up pressure of approximately 6 kPa.

Figure 1 - cylinder regulator setting pressure

Purging a gas installation (out of service)

- Ensure that the purging and inert gas equipment is correctly installed and that all valves downstream of the nitrogen gauge are closed.

- Record the reading of the nitrogen cylinder pressure gauge.

- Slowly pressurise the section of pipe between the nitrogen gauge and quarter turn ball valve isolating the installation (See Figure 1).

- Open the quarter turn ball valve to introduce nitrogen to the gas installation. Leak test all connections and fittings between the nitrogen cylinder and the consumer piping. Open the isolation valve at the inlet to the purge hose and check the purge hose and stack connections for leaks (Refer to Figure 1).

- Slowly open the main valve on the purge stack. As this valve is opened the sound of flowing gas should be heard. If desired, a manometer may be connected to the purge stack to determine if gas flow is occurring.

- Continue purging until the required volume of nitrogen has been injected and if replacing gas with nitrogen a reading of 0.5% gas (10% LEL) or less is measured from the gas sampling valve on the purge stack, using a suitable gas detector.

- Turn off the main valve on the purge stack.

- Disconnect the purge hose and the hose inlet valve from the installation, capping off immediately to avoid gas escaping and air re-entering the line.

- Transfer the purge stack and hose to the end of the branch nearest the meter and repeat the procedure.

- Continue purging all branches, moving away from the meter, until the whole installation is filled with nitrogen.

Testing for completion of a purge

Replacing air with nitrogen

Field analysis and testing to prove the completion of an air to nitrogen purge is not practical. Therefore it is important to ensure that a sufficient volume (See section - Calculating the volume of inert gas required) of nitrogen has been used for a complete and successful purge.

Replacing gas with nitrogen

In this case it can be proven that the fuel gas has been eliminated, by testing a sample of the purged gas with a suitable gas detector. (See section – Purging a gas installation out of service – Step 6).

Additional Information

Determining the volume of consumer piping (approximate litres per metre length)

Table D.4.1 Appendix D - AS/NZS 5601.1:2022; provides an approximate value for volume in litres per metre of pipe length. If the piping material being used in the installation is not listed in Table D.4.1, then the manufacturers’ specifications should be referred to.

Note: (If a volume value in m3 is required; divide litres by 1000 = m3).

Nitrogen cylinder volumes

Nitrogen cylinders are available from several manufacturers and supplied in a variety of sizes, with differing volumes and fill pressures. It’s recommended that the nitrogen supplier is consulted for advice on how best to supply the nitrogen, for example one or two cylinders, and also to clarify the cylinder fill pressures in each case.

Establishing the amount of nitrogen used

The amount of nitrogen introduced to the piping installation during the purge process, can be determined with the use of the nitrogen cylinder pressure gauge.

Begin by noting the fill pressure at the nitrogen cylinder pressure gauge before use and then again at regular intervals during the purge process (that is, noting the total amount of pressure drop). For compressed gases like nitrogen, the pressure in the cylinder is proportional to the content, whereby if the pressure drops by 50%, then 50% of the nitrogen gas has been used.

For example: If the nitrogen volume was 2m3 before use and had a fill pressure of 16,000kPa; then a drop in pressure of 50% (the gauge now reads - 8,000kPa) would indicate 1m3 of nitrogen has been used during the purge and 1m3 of nitrogen remains in the cylinder.

Note: The nitrogen supplier should always be consulted to confirm this example applies to their supplied cylinder.

Calculating the total volume of nitrogen required to purge a gas pipe network - a worked example

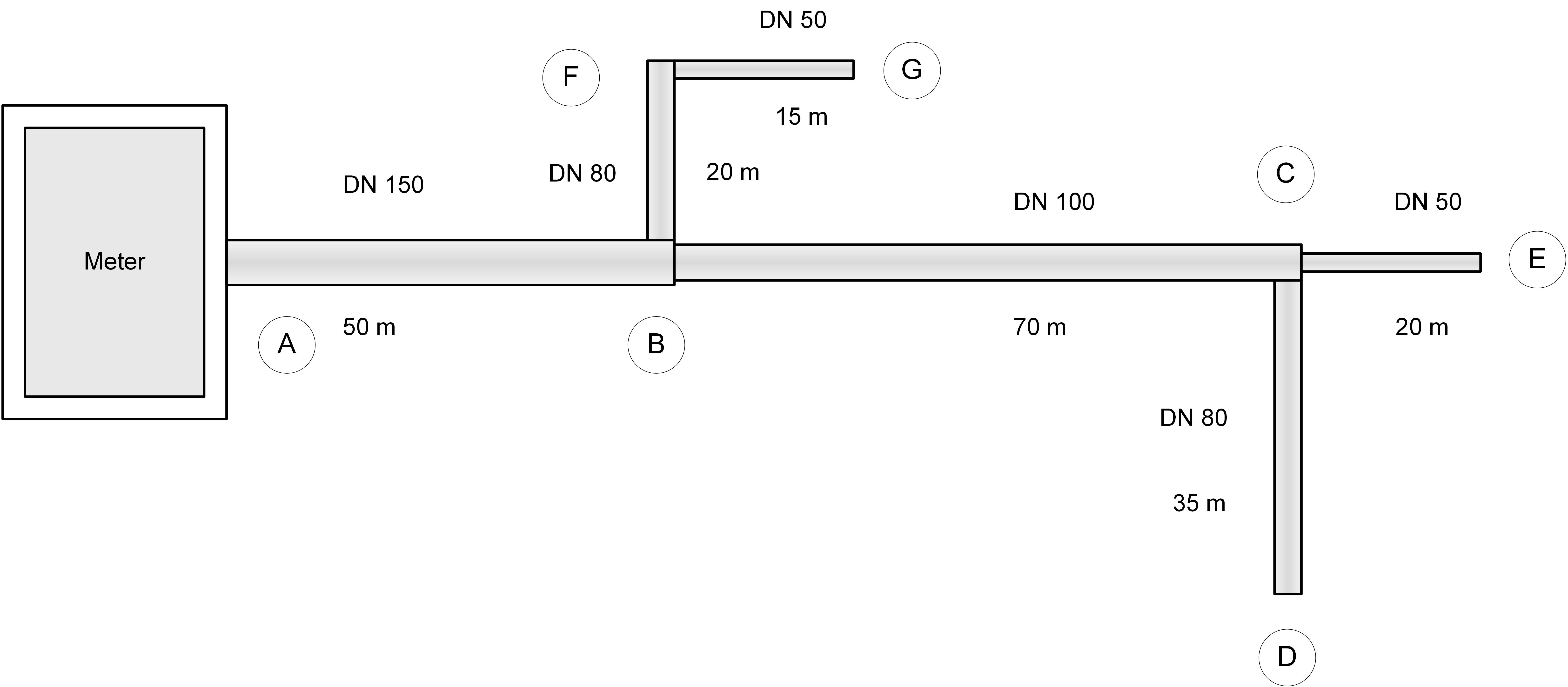

Figure 2 – a hypothetical Type B copper pipe installation

Table 4 – determine the consumer piping volume

Using manufacturer's information and Table D.4.1 for approximate litres per metre length of pipe

| Main run (A-D) | Branch (B-G) | Branch (C-E) |

|---|---|---|

Main run pipe volume = (A-B) + (B-C) + (C-D) = (50 x 16.70) + (70 x 7.58) + (35 x 4.17) = 835 + 530.6 + 145.95 = 1511.55 litres | Branch pipe volume = (B-F) + (F-G) = (20 x 4.17) + (15 x 1.83) = 83.4 + 27.45 = 110.85 litres | Branch pipe volume = (C-E) = (20 X 1.83) = 36.6 litres |

Volume of nitrogen for the main run (A-D) = 1511.55 x 1.5 = 2267.32 litres | Volume of branch (B-G) = 110.85 x 1.5 = 166.27 litres | Volume of branch (C-E) = 36.6 x 1.5 = 54.90 litres |

Total amount of nitrogen required

(A-D) + (B-G) + (C-E)

= 2267.32 + 166.27 + 54.90

= 2488.49 litres or 2.49m3

Note: (Divide litres by 1000 for m3)

Determining the amount of nitrogen to use

To ensure a complete purge, the whole consumer pipe must be filled with nitrogen. In this example, 2.49m3 of nitrogen will be required. Consult your nitrogen supplier to determine the cylinder sizes required, to obtain the total amount of nitrogen required.

Recommended purging kit

The recommended purging kit shown in Figure 3 has been designed to assist with purging gas to the atmosphere.

Figure 3 - recommended purging kit

Some general points to remember about the kit and purging

- The hose diameter should fit with the purge stack and 25 millimetres is recommended (as smaller diameters may result in a slower purge).

- Avoid polyethylene pipe, which may be subject to sparking from static electricity.

- There must be no ignition sources within 6 metres of the purge area. Use of suitable signage (for example- no ignition sources/smoking/mobile phones); and a method for cordoning off the purge area (for example - barriers, barricades, fencing or bollards with hazard tape) is recommended.

- Flame arrester use is optional, but if a flame arrester is used, ensure it is not unduly restrictive to the flow of gas and is cleaned prior to use.

- The purge flow must be maintained and supervised at all times, until the purge process is complete.

Date: 05/03/2026 11:22

Controlled document

The currency and accuracy of this document cannot be guaranteed once printed or saved to a storage device. If in doubt, please check the ESV website for the current version.

Reviewed